Schweizer precision engine components

Products

Looking forward to hearing from you!

Engine components

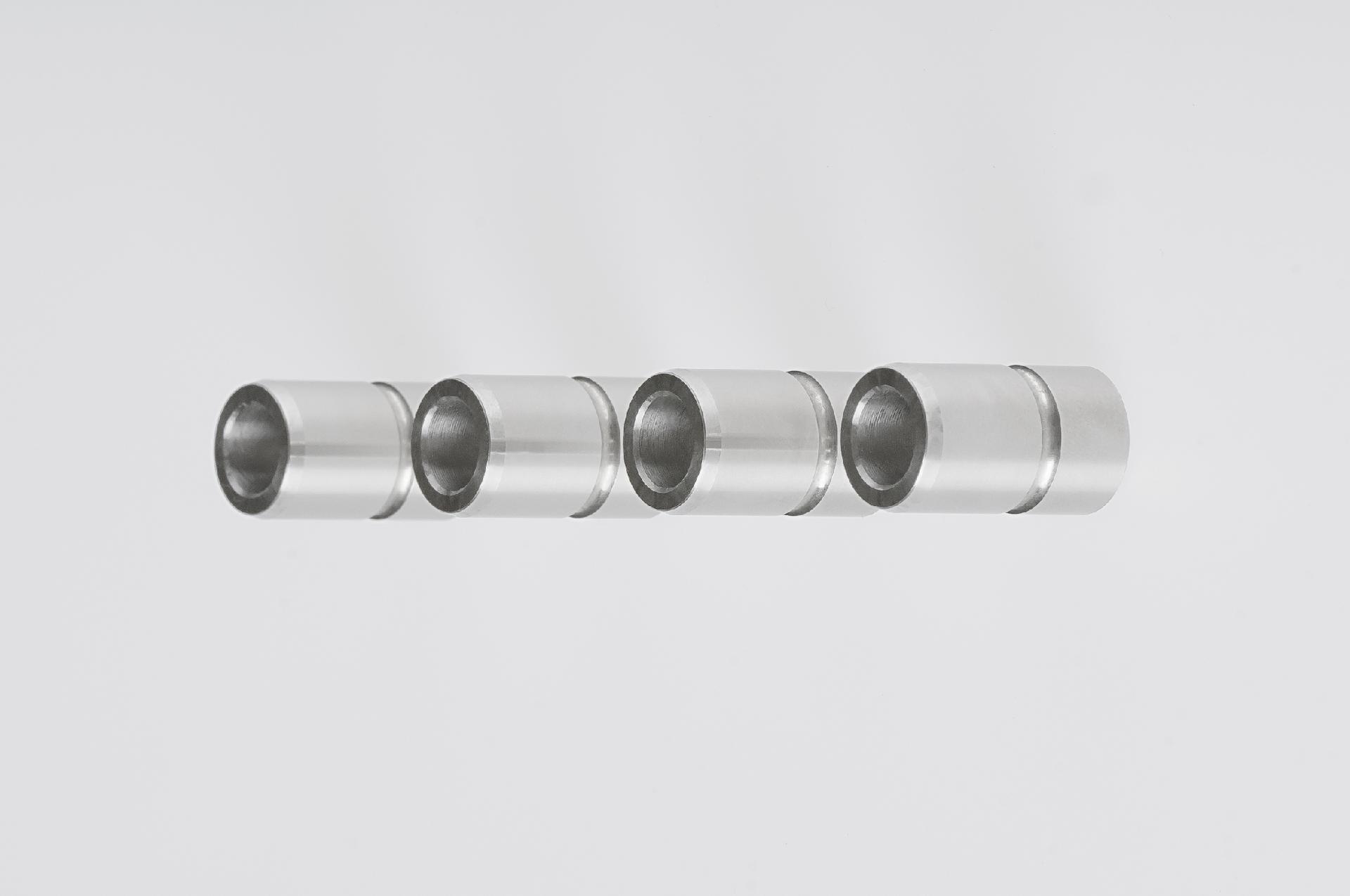

Valve guides are the main focus of our engine component production, here we work to our customer specifications and requirements.

We manufacture valve guides with rough and finished bores up to a length of 200 mm from grey cast iron in various compositions. In addition, we produce valve guides made of various copper alloys such as CuZn40Al2, Kuprodur or Thermo-Hedul FS and E as well as from sintered metal.

Steering components

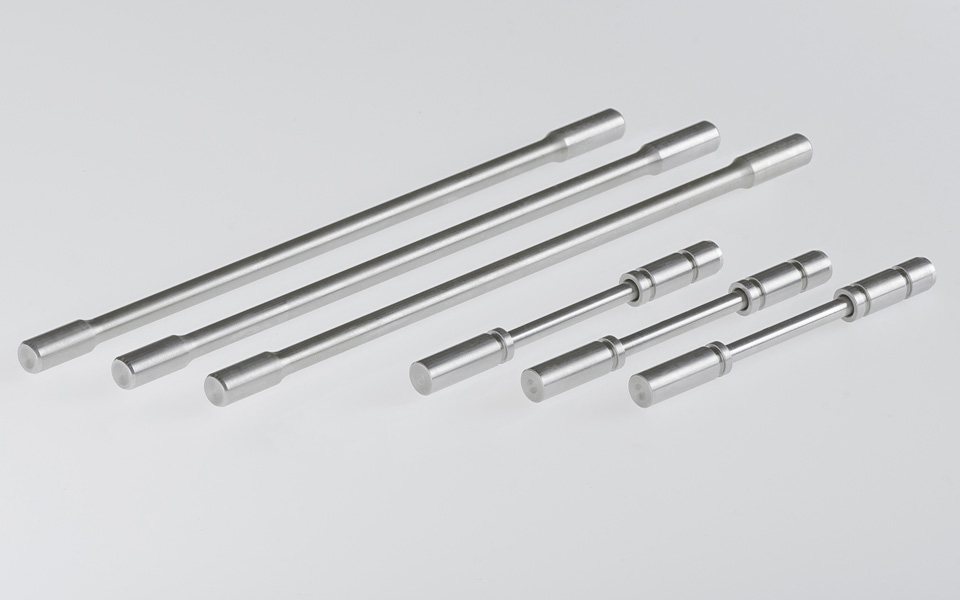

Our steering component programme covers products made of grey cast iron as well as steel. Valve bushings for example are manufactured from grey cast iron, whilst torsion bars, flexural bar and PCF torsion bars are made of steel, for example 51CrV4. Our steering components are used in power steering systems.

In the production of our steering components, we employ modern manufacturing technologies such as cold forming and laser welding.

Turbocharger components

We mass-produce components for exhaust turbochargers from special high temperature materials.

Looking forward to

hearing from you!

Production steps in detail

1. 1. The blank

Grey cast iron has proven its worth particularly for the manufacture of valve guides used in large diesel engines such as ship engines, electricity generators or truck engines. It has very good thermal conductivity properties, and, moreover, grey cast iron with a higher phosphorus content has very good dry-running properties due to its favourable graphite structure and its oil retaining pockets. The following is a description of the cast iron valve guide production in four steps from the blank to the ground final part.

2. Internal machining

The valve guide secures the valve’s axial location, and thus the bore must be machined with the highest precision.

3. Turning

During the first turning process, the outside diameter is machined. During this process, the coaxiality of the bore to the outside diameter needs to be considered. Subsequently, various forms and grooves are turned on both the outside and in the bore of the workpiece.

4. Grinding

Centreless grinding is the last machining operation. The outside diameter of the valve guide is ground on CNC grinding machines within very narrow tolerances. Here, particular attention needs to be paid to the surface roughness and the geometry of the outside diameter.