Schweizer precision engine components

Quality

Looking forward to hearing from you!

Quality

Our modern quality management system involves all our employees. Each and every employee assumes responsibility for the quality of our products and the fulfilment of our quality goals.

Important core elements of our quality management system

Customer orientation

Constant improvement

Controlled processes

Zero-defects approach

Using state-of-the-art measuring instruments, inspection systems and our CAQ system, the quality of our products is ensured from receipt of the raw material, through every production stage up to the final inspection. Instruction and training are also important elements of our total quality management philosophy.

We have been certified according to DIN ISO EN 9002 since 1998 and according to DIN ISO EN 9001:2008 since 2009. Moreover, our QM system is oriented on ISO TS 16949.

Looking forward to

hearing from you!

Inspection procedures

The raw materials employed in the manufacturing process undergo various material properties tests such as hardness testing.

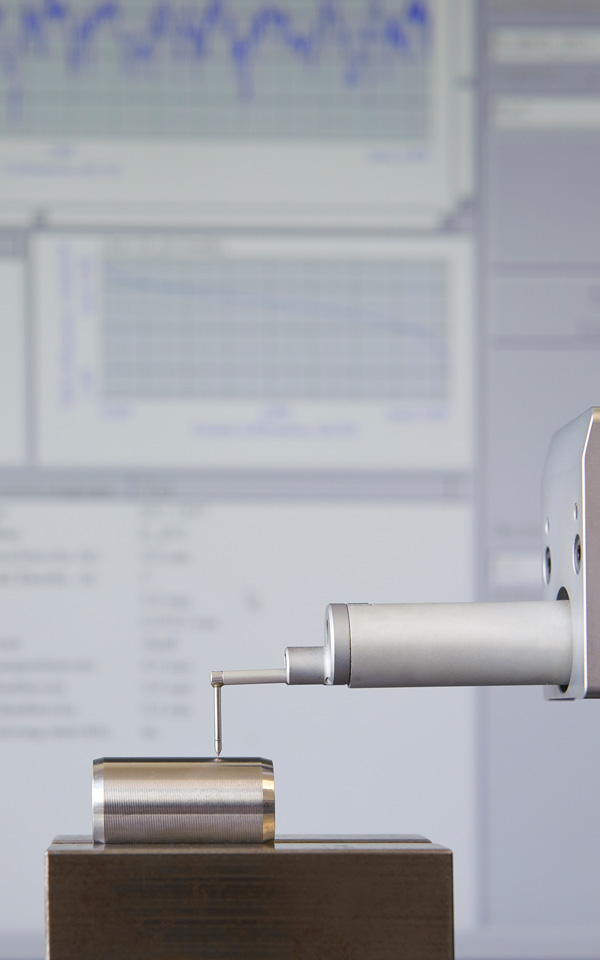

In order to inspect and measure the surface finish, we use modern surface measurement techniques such as the profile method.

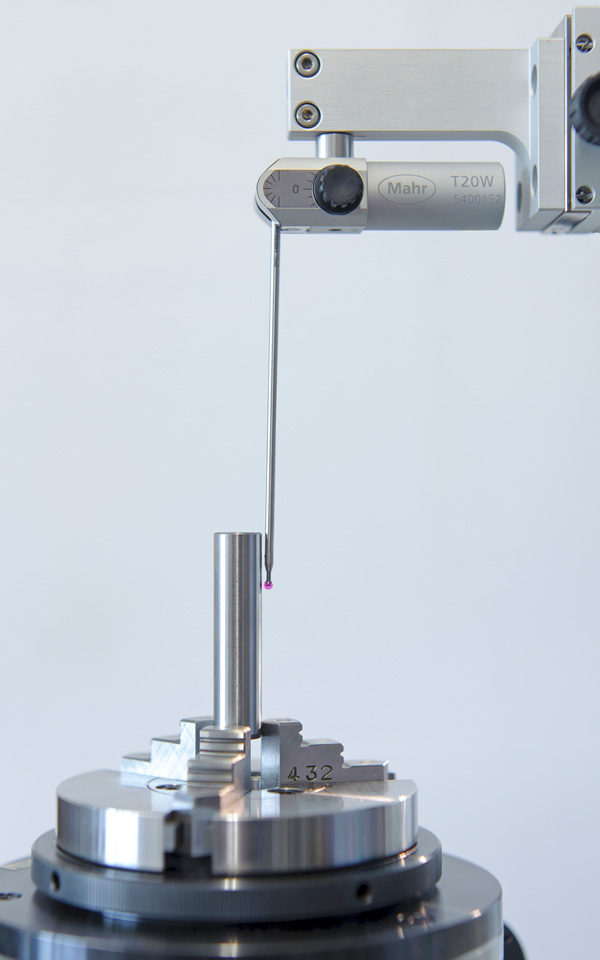

We carry out precise form measurements to determine the geometry of components subject to tight tolerances.

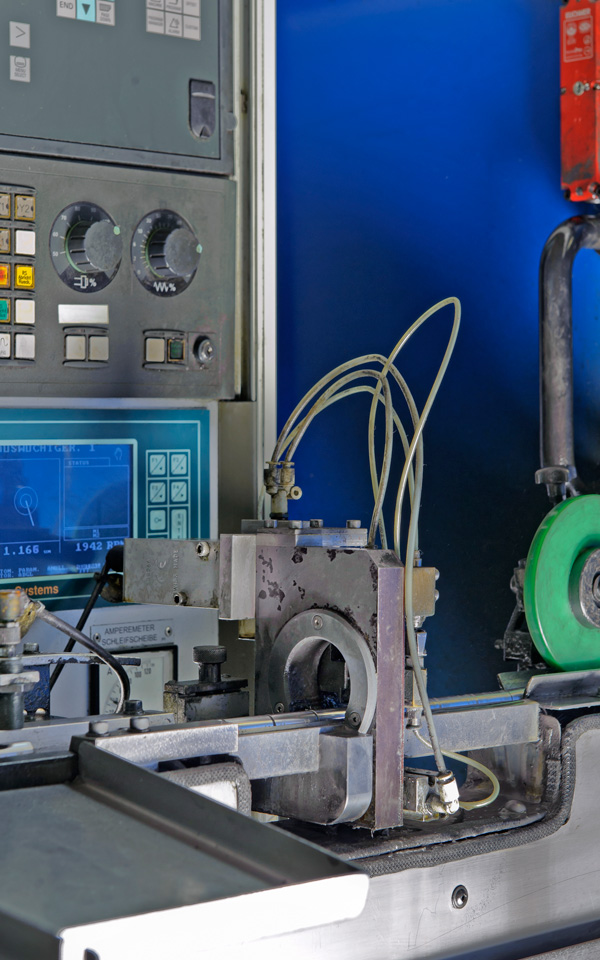

After some machining operations, post process measurements are carried out. Thus, the critical features of the workpiece are submitted to a 100% inspection.

Furthermore, the key features of the workpiece undergo a 100% inspection on bespoke automatic test benches.